Want to know the origin of mercerized cotton?

-

July 22, 2025

-

By: Rose Woman Scarf

-

33

Introduction

In the late autumn of 2018, the Clignancourt antique market on the Left Bank of Paris welcomed a special visitor. Art historian Emma Lebrun found a dark green silk scarf with pearl luster in an inconspicuous shop. It feels as smooth as silk but has the simplicity of cotton. “This is a mercerized cotton scarf from the 1920s,” the owner Pierre stroked the treasure, “It witnessed the era when Coco Chanel liberated women’s necks.”

This scarf aroused Emma’s curiosity-why can a seemingly ordinary cotton fabric have such a gorgeous luster? What kind of craft heritage is hidden behind this? Let us unveil the thousand-year veil of mercerized cotton scarves together.

The origin of mercerized cotton and development

In 1844, British chemist John Mercer accidentally discovered that when cotton cloth is treated in concentrated alkali solution, it will shrink and produce a permanent luster-this is the famous “mercerization”. According to Mercer’s laboratory notes collected by the British Library, this discovery was not taken seriously at first. It was not until 1890 that Horace Lowe improved the process and made mercerized cotton truly commercially produced.

In the early 20th century, Swiss textile magnate Jacob Mueller further improved the process, increasing the strength of mercerized cotton by 20-50% and the color absorption capacity by up to 25% (according to the Journal of Chemical Processing of Textiles, 2003). This improvement makes mercerized cotton an ideal material for high-end silk scarves, retaining the breathability of cotton and obtaining a silk-like luster.

Compared with ordinary cotton, the cross-section of mercerized cotton fibers changes from waist-round to nearly round, and the surface is smoother (Scanning electron microscopy observation results, Fiber Science, 2015). Compared with silk, mercerized cotton is easier to care for and more affordable, which explains why luxury brands such as Hermès have launched mercerized cotton series.

The production process of mercerized cotton scarves

The birth of a top-grade mercerized cotton scarf is a perfect combination of traditional craftsmanship and modern technology. The textbook of ARSUTORIA, a famous Italian textile school, records this process in detail:

- Cotton selection: usually Egyptian long-staple cotton or sea island cotton, the fiber length must be more than 35mm

- Spinning: high-count combing (more than 200 needles per inch)

- Mercerization: immersion in concentrated alkali solution (290g/L NaOH) at -23℃ under tension, followed by acid neutralization

- Dyeing: reactive dyes are fixed at pH10-11, and the temperature is strictly controlled at 60℃

- Finishing: Bio-enzyme polishing treatment to remove surface fluff

The 1927 process manual preserved by the Lyon Textile Museum in France shows that it took 6 weeks to complete these processes at the time, while modern automated production only takes 72 hours. However, top brands such as Etro still insist on some manual processes, and each scarf must undergo 7 quality inspections.

Advantages:

Mercerized cotton is named for its mercerized luster, and the luster of double mercerized cotton after two treatments will be better. The fabric not only retains the softness, comfort and warmth of cotton fibers, but also has more elasticity and drape after mercerization, which is why this fabric is popular.

Disadvantages:

Mercerized cotton is thin and easy to break, so avoid strong stretching or frequent friction when wearing it. In principle, it can be machine washed, but it is not recommended. If the label on the clothes says it cannot be machine washed, it cannot be machine washed. The complex processing process has increased the production cost of mercerized cotton, which is also the reason why the fabric price is higher.

The cultural significance of mercerized cotton scarves

In the textile exhibition hall of the British Museum, a fragment of Indian cotton fabric from 300 BC shows the prototype of the early mercerization effect-craftsmen used shells to polish cotton cloth to make it shiny.

The 20th century was the golden age of scarves:

- In the 1930s, Elsa Schiaparelli printed surrealist art on scarves

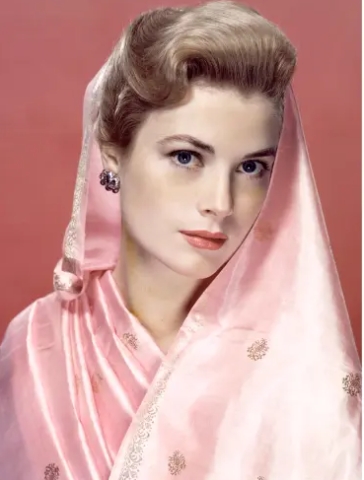

- In 1956, Grace Kelly used scarves to fix her broken arm in a classic look

- In the 1990s, Princess Diana pioneered the “scarf-to-top” dressing method

Japanese kimono research expert Yuko Tanaka pointed out in “The Civilization History of Cloth”: “Mercedes-cotton scarves are the crystallization of the wisdom of textiles in the East and the West. They use chemical methods to achieve the gloss effect that Orientals pursue with physical polishing.”

How to select and maintain mercerized cotton scarves

Selection tips:

- Observe the scarf against the light. High-quality mercerized cotton should have a uniform silk-like luster

- After rubbing and unfolding, high-quality products should have no obvious creases (French Textile Testing Association Standard NF G07-173)

- Drip test: High-quality mercerized cotton absorbs water 30% faster than ordinary cotton

Maintenance points:

- Washing: Hand wash in cold water, use pH neutral silk detergent

- Ironing: Steam iron at 160℃, keep 2-3cm distance

- Collection: Roll storage is better than folding, avoid direct contact with mothballs

Sarah Stevens, textile restorer at the Metropolitan Museum of Art, recommends: “Antique silk scarves should be moisturized by professional institutions every ten years, using a maintenance solution similar to human sweat (weakly acidic solution with pH 5.5).”

References:

- “Chemical Treatment of Textiles”, 3rd edition, Springer Publishing, 2009

- British Museum Textile Research Paper Series, 2012-2018

- Archives of the French Textile Crafts Protection Association, No. TEX-FR-77100

- Photocopy of Mercer Laboratory Original Notes, London Science Museum

- “The Civilization History of Cloth”, Yuko Tanaka, Iwanami Shoten, 2005

Leave a comment